- Home Page

- Company Profile

-

Our Products

- Chapati Making Machine

- Semi Automatic Chapati Making Machine

- Chapati Making Machine Manufacturer

- Automatic Chapati Making Machine

- Chapati Cum Puffer Plate

- Automatic Chapati Making Machine

- Fully Automatic Chapati Making Machine

- Chapati Making Machine Commercial 500 roti/hr

- CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel

- Chapati Making Machine Commercial 2000 roti/hr

- Chapati Making machine

- Food Preparation Equipments

- Hot Equipments

- Cold Equipments

- Table Racks

- SS Trolleys

- Washing Equipments

- Fast Food Equipment Table

- Industrial Kitchen Equipment

- Juice Dispenser

- Commercial Kitchen Design Service

- Chapati Making Machine Renting Service

- AMC For Chapati Making Machine

- Fried Ice Cream Machine

- Roti Making Machine

- Food Preparation Equipment

- Dough Kneader

- Chapati Making Machine

- Contact Us

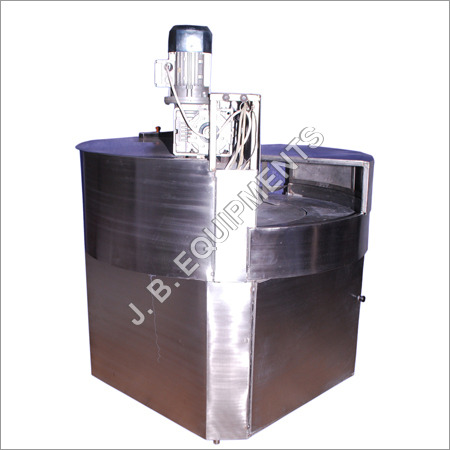

CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel

Price 199999.0 INR/ Piece

MOQ : 1 Piece

CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel Specification

- Product Type

- CHAPATI MACKING MACHINE

- General Use

- COMMERCIAL USE

- Material

- SS

- Type

- Roti Making Machine

- Capacity

- 1000 Pcs/hr

- Weight (kg)

- 300 Kilograms (kg)

- Product Thickness

- 2 Millimeter (mm)

- Product Shape

- Round

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Heating System

- Electric

- Voltage

- 3.5 Watt (w)

- Dimension (L*W*H)

- 72*24*48 Inch (in)

- Feature

- High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

- Color

- SILVER

CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- NEW DELHI

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Delivery Point (DP), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 2 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN PACKAGING

- Main Export Market(s)

- North America, Eastern Europe, Asia, Western Europe, Africa, Australia, Central America, South America, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO CERTIFIED

About CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel

Make fresh, soft, and perfectly round chapatis in seconds! Our fully automatic chapati-making machine is built with stainless steel for durability and hygiene. Ideal for hotels, restaurants, canteens, and catering services, it saves time, reduces labor, and ensures consistent quality every time.

- High capacity production

- Uniform size & thickness

- Energy-efficient & easy to use

- Hygienic, durable & low maintenance

| Usage/Application | Industrial |

| Design Type | Customized |

| I Deal In | New Only |

| Country of Origin | Made in India |

| Machine Body Material | stainless steel |

High-Efficiency Roti Production

Designed for commercial settings, this chapati making machine streamlines bulk production with a capacity of 1000 rotis per hour. Its robust electric heating system and SS construction ensure reliability, while the non-stick surface minimizes downtime between batches. The result is consistently round, evenly-cooked chapatis, boosting productivity and reducing manual labor.

User-Friendly, Low-Noise Operation

Though highly efficient, the machine operates with remarkably low noise, contributing to a more comfortable working environment. Easy-to-use controls, simple cleaning due to the non-stick coating, and the absence of complicated computerized systems make it ideal for staff with varying skill levels. Its energy-efficient design also reduces operational costs.

Eco-Friendly and Safe Design

This machine is built with environmental consciousness in mind, utilizing electric heating and food-safe materials. The SS body prevents corrosion and contamination, ensuring food safety. With no PLC or computing components, maintenance is straightforward and dependable for long-term use in demanding environments.

FAQ's of CHAPATI MAKING MACHINE Commercial 1000 roti/hr Stainless Steel:

Q: How does the commercial chapati making machine work?

A: The machine utilizes an electric heating system and non-stick coated surfaces to automate the process of pressing and cooking dough into round chapatis. Operators manually feed dough or dough balls, and the machine handles the shaping and baking, delivering up to 1000 rotis per hour with uniform thickness and size.Q: What are the benefits of using this chapati making machine in commercial kitchens?

A: Key benefits include high output, consistent product quality, reduced manual labor, and energy efficiency. The non-stick coating simplifies cleaning, while the stainless steel construction ensures hygiene and durability. Low noise levels make it suitable for prolonged use in busy environments.Q: When is the ideal time to use this roti making machine?

A: This machine is particularly valuable during peak food service hours or large events when rapid production of chapatis is essential. It enables kitchens to meet high demand without compromising on quality or speed.Q: Where can this chapati making machine be installed?

A: The machine is designed for installation in spacious commercial kitchens such as those in hotels, restaurants, cafeterias, food processing units, and catering services. Ensure there's adequate space (72*24*48 inches) and a compatible electrical supply for optimal performance.Q: What is the step-by-step process for using the machine?

A: Begin by preparing the chapati dough. Feed dough balls into the machine's input section. The machine presses, shapes, and cooks the chapatis using its electric heating system. Finished rotis are collected from the output tray, ready for serving or packaging.Q: Is the machine suitable for different types of dough or only standard wheat flour?

A: While optimized for standard wheat flour chapati dough, the machine's multi-functional capabilities can accommodate other similar doughs, provided they meet the recommended consistency and hydration for safe processing.Q: How does the non-stick coating benefit commercial users?

A: The non-stick coating prevents chapatis from sticking to the machine surfaces, reducing waste and cleaning time. This feature boosts operational efficiency and helps maintain the machine's optimal hygiene for high-volume production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Chapati Making Machine Category

Automatic Chapati Making Machine

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Stainless Steel

Type : Roti Making Machine

Feature : High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

Chapati Cum Puffer Plate

Price 30000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : SS

Type : Roti Making Machine

Feature : Low Noise, High Quality, High Efficiency

Chapati Making machine

Price 130000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless Steel

Type : Other, Automatic

Feature : Other, Energy Efficient, Easy to Clean, High Output

Automatic Chapati Making Machine

Price 250000 INR

Minimum Order Quantity : 1 Unit

Computerized : No

Material : Stainless Steel

Type : Roti Making Machine

Feature : High Quality, Non Stick Coating, Environment Friendly, High Efficiency, Multi Functional, Low Noise

|

J.B. EQUIPMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry